25 Hp Horizontal Centrifugal Pump

Why buy from us?

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Ask a Question About This Product

25 Hp Horizontal Centrifugal Pump

from

$4,557.85

Ex Tax: $4,557.85

- Stock: In Stock

- Model: HZTOHZ-HCP-18d5KW

- Weight: 1.00

- SKU: HZTOHZ-HCP-18d5KW

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

$972.85

Ex Tax:$972.85

$897.77

Ex Tax:$897.77

$1,184.13

Ex Tax:$1,184.13

$1,054.74

Ex Tax:$1,054.74

$2,518.44

Ex Tax:$2,518.44

$162.46

Ex Tax:$162.46

$206.49

Ex Tax:$206.49

$195.82

Ex Tax:$195.82

$292.46

Ex Tax:$292.46

$218.69

Ex Tax:$218.69

25 hp horizontal centrifugal pump with 29.2m3/h maximum flow, 103m maximum head, and 50mm diameter of inlet and outlet.

Features:

- The centrifugal pump has a horizontal structure. The diameter of the inlet and outlet are the same. If a protective cover is added, it can be used in the open air.

- It is easy to install and maintain. There is no need to dismantle the pipeline system, just lift off the conjunction flat nut of the vertical pump. Then, all the rotor parts can be taken out.

- A horizontal centrifugal pump can operate in series and parallel connection according to the requirements of flow and head.

- The installation angle of the pump outlet can be 0°, 90°, or 180° to meet different connection occasions.

Specifications:

| Model | HZTOHZ-HCP-50-315IB | ||

| Weight | 260kg | ||

| Size | 570*840*360mm | ||

| Power | 25 hp (18.5 kW) | ||

| Phase | 3 phase | ||

| Input voltage * | AC 220V, 230V, 240V, 380V, 400V, 415V, 440V, 460V, 480V | ||

| Input frequency * | 50Hz, 60Hz | ||

| Flow (min. flow to max. flow) | 15.7m3/h (12 gpm, American system) | 22.5m3/h (99 gpm, American system) | 29.2m3/h (159 gpm, American system) |

| Head (max. head to min. head) | 103m (338ft) | 101m (331ft) | 98m (322ft) |

| Efficiency | 39% | 39% | 39% |

| Inlet diameter | 50mm (2 inch) | ||

| Outlet diameter | 50mm (2 inch) | ||

| Installation angle of outlet | 0°, 90° and 180° | ||

| Nominal diameter of impeller | 315mm | ||

| Pump type | Booster pump | ||

| Number of stages | Single stage | ||

| Motor type | Y/Y2 series motor | ||

| Motor speed | 2900rpm | ||

| Impeller material | 304/316 stainless steel | ||

| Seal material | 304 stainless steel, tungsten carbide, fluorine rubber | ||

| Inlet max. pressure | 1MPa (145 psi) | ||

| (NPSH)r | 2.5m | ||

| Usage | Water or liquids compatible with pump component materials. 1. The volume of solid particles should be less than 0.1% in unit volume, and the granularity should be less than 0.2mm. 2. The temperature should be lower than 60℃. | ||

| Environment | Temperature: <40℃, humidity: <95%, altitude<1000m | ||

| Warranty | 12 months | ||

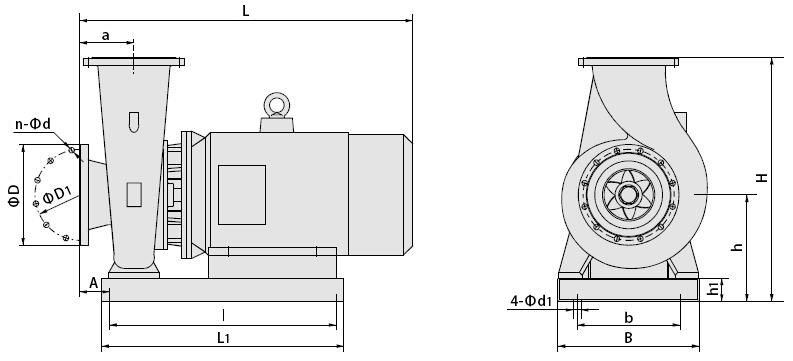

Horizontal centrifugal pump dimension (unit: mm):

| Boundary dimension | Base dimension | Flange dimension | |||||||||||

| h | H | L | a | A | L1 | B | l | b | h1 | 4-Φd1 | D | D1 | n-Φd |

| 300 | 570 | 840 | 125 | 85 | 620 | 360 | 570 | 260 | 100 | 4-Φ18 | Φ165 | Φ125 | 4-Φ18 |

Tips: Overhauling method of the packing seal of the single-stage centrifugal pump

- Clean the centrifugal pump stuffing box and check if the bearing outer surface has any scratch or burr. The stuffing box should be maintained clean, and the bearing's outer surface should be lubricated.

- Check the bearing bounce. The imbalanced amount of the rotor bounce should be within the allowable scope, avoiding too serious vibration, which is not good for the stuffing.

- Apply sealant or lubricant applicable to the media in the stuffing box and the outer surface of the bearing.

- As to the stuffings packed in rolls, it is required to first take a wooden rod with the same size as the shaft neck, wind the stuffing ring on it, and then cut with the knife. The cut surface shows a 45° slope.

- The stuffings should be filled in pieces. It is not allowed to fill several pieces in one time. The method is to take one piece of stuffing smeared with the lubrication agent. Hold each end of the stuffing interface with two hands, spread along the axial direction, make it twist, and then inject it into the shaft neck. It is not allowed to spread in the radial direction to avoid the irregular interface.

- Take one metal shaft sleeve with the same material or softer material as the stuffing ox, push the stuffing deeply into the box, and exert a certain pressure to the shaft sleeve with the gland to shrink the stuffing. The estimated shrinkage amounts are 5%~10% and 20%. Afterward, roll the shaft for one week and take out the shaft sleeve.

- Fill in the second and third pieces in the same way. Attention: when the stuffing pieces reach 4-8, they shall be staggered by 90°in filling. The second stuffing should be staggered by 180°. The 3-6 pieces should be staggered by 120° to avoid interface leakage.

- After filling one stuffing, please tighten with the gland, but the compression force should not be too heavy. In the meantime, please rotate the shaft manually, enabling the installing compression to spread in a parabo. Afterwards, release the gland.

- Please carry out the working experiment. If it is unable to be sealed, the stuffing should be compressed tighter. If the heating is too serious, please release it. Please adjust in this way until the leakage is in the dripping type and the heat is not too high(the temperature of the stuffing part is only 30~40℃ than the ambient temperature) before putting it into operation.

In addition, when repairing or exchanging the mechanical seal of the packing seal of the single-stage centrifugal pump, there is no need to disassemble the motor and pump gland.

Horizontal Centrifugal Pump User Manual

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.