20 Hp Horizontal Centrifugal Pump

Why buy from us?

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Ask a Question About This Product

20 Hp Horizontal Centrifugal Pump

from

$4,197.68

Ex Tax: $4,197.68

- Stock: In Stock

- Model: HZTOHZ-HCP-015KW

- Weight: 1.00

- SKU: HZTOHZ-HCP-015KW

Available Options

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

Create unlimited custom product blocks and display them in accordions or tabs or open blocks. Each block can be assigned to all products at once or specific products according to advanced criteria.

$972.85

Ex Tax:$972.85

$897.77

Ex Tax:$897.77

$1,184.13

Ex Tax:$1,184.13

$1,054.74

Ex Tax:$1,054.74

$2,518.44

Ex Tax:$2,518.44

$162.46

Ex Tax:$162.46

$206.49

Ex Tax:$206.49

$195.82

Ex Tax:$195.82

$292.46

Ex Tax:$292.46

$218.69

Ex Tax:$218.69

20 hp horizontal centrifugal pump with 32.5m3/h maximum flow, 82m maximum head, and 65mm diameter of inlet and outlet.

Features:

- The centrifugal pump has a horizontal structure. The diameter of the inlet and outlet are the same. If a protective cover is added, it can be used in the open air.

- It is easy to install and maintain. There is no need to dismantle the pipeline system, just lift off the conjunction flat nut of the vertical pump. Then, all the rotor parts can be taken out.

- A horizontal centrifugal pump can operate in series and parallel connection according to the requirements of flow and head.

- The installation angle of the pump outlet can be 0°, 90°, or 180° to meet different connection occasions.

Specifications:

| Model | HZTOHZ-HCP-65-250 | ||

| Weight | 230kg | ||

| Size | 520*795*330mm | ||

| Power | 20 hp (15kW) | ||

| Phase | 3 phase | ||

| Input voltage * | 220V, 230V, 240V, 380V, 400V, 415V, 440V, 460V, 480V | ||

| Input frequency * | 50Hz, 60Hz | ||

| Flow (min. flow to max. flow) | 17.5m3/h (77 gpm, American system) | 25m3/h (110 gpm, American system) | 32.5m3/h (143 gpm, American system) |

| Head (max. head to min. head) | 82m (269ft) | 80m (262ft) | 76.5m (251ft) |

| Efficiency | 39% | 50% | 52% |

| Inlet diameter | 65mm (2-1/2 inch) | ||

| Outlet diameter | 65mm (2-1/2 inch) | ||

| Installation angle of outlet | 0°, 90° and 180° | ||

| Nominal diameter of impeller | 250mm | ||

| Pump type | Booster pump | ||

| Number of stages | Single stage | ||

| Motor type | Y/Y2 series motor | ||

| Motor speed | 2900rpm | ||

| Impeller material | 304/316 stainless steel | ||

| Seal material | 304 stainless steel, tungsten carbide, fluorine rubber | ||

| Inlet max. pressure | 1MPa (145 psi) | ||

| (NPSH)r | 2.5m | ||

| Usage | Water or liquids compatible with pump component materials. 1. The volume of solid particles should be less than 0.1% in unit volume, and the granularity should be less than 0.2mm. 2. The temperature should be lower than 60℃. | ||

| Environment | Temperature: <40℃, humidity: <95%, altitude<1000m | ||

| Warranty | 12 months | ||

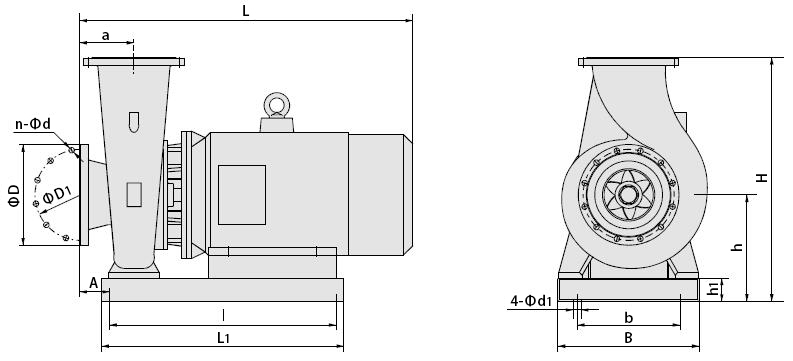

Horizontal centrifugal pump dimension (unit: mm):

| Boundary dimension | Base dimension | Flange dimension | |||||||||||

| h | H | L | a | A | L1 | B | l | b | h1 | 4-Φd1 | D | D1 | n-Φd |

| 280 | 520 | 795 | 100 | 65 | 560 | 330 | 510 | 230 | 100 | 4-Φ18 | Φ185 | Φ145 | 4-Φ18 |

Tips: Centrifugal pump troubleshooting - serious vibration of pump and abnormal noise

- If the centrifugal pump foundation is stale

When vibration occurs, please first check if the anchor bolts of the centrifugal pump are tight. If they are not tightened, it will cause the centrifugal pump to vibrate. Please also consider whether the foundation strength of the foot is sufficient. Sometimes, due to design reasons, the soft foundation can also cause vibration. - Coupling alignment

Many centrifugal pumps are driven by couplings, and there are many types of couplings. The alignment of the normal three-paw coupling directly affects the normal operation and service life of the coupling, shaft, bearing, and machine seal. - Alignment

Improper alignment is also a common reason causing vibration. The alignment should be regulated in the specified range according to the standard strictly. - Bearing inspection

Check if the bearing is correctly installed or damaged. - Adjustment of the rotor central position

The water pump rotor must be concentric with the stator, otherwise, friction will be generated in the water pump operation, thus causing variation. - Shaft curving and rotor measurement

If the cause of the variation can not be found externally, the pump can only be disassembled. Please firstly measure and correct the bending of the shaft. After confirming that there is no problem, the rotor will be mounted, and the overall sway and scoring will be measured. If it exceeds the standard, it must be corrected. - Inspection of the dynamic and static balance

After the centrifugal pump is disassembled, to avoid vibration when the pump is turned on, the impeller should also be conducted with the static balance test. - Influence of external conditions on the water pump

When all the problems of the pump itself are eliminated, if the vibration problem still cannot be solved, the influence of external conditions on the pump should also be considered. For example, the resonance caused by the natural frequency of the pump base is similar to the vibration frequency, the vibration of the pump caused by the failure of the prime motor, and the strong counterpart used for the connection between the pipeline and the pump will also probably cause abnormal vibration of the pump.

Horizontal Centrifugal Pump User Manual

Builder in Product TAB

NEW! Since Journal 3.2, the much improved T.A.B (Tabs Accordion Blocks) system supports the page builder inside the tab content. Unlimited Blocks, Tabs or Accordions with any HTML content or the builder interface (supporting custom rows/columns/modules) can be assigned to any individual product or to certain groups of products, like entire categories, brands, products with specific options, attributes, price range, etc.

You can indicate any criteria via the advanced product assignment mechanism and only those products matching your criteria will display the modules.

Also, any module can be selectively activated per device (desktop/tablet/phone), customer login status and other criteria. Imagine the possibilities.