100 Hp Horizontal Centrifugal Pump

Why buy from us?

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Ask a Question About This Product

- Stock: In Stock

- Model: HZTOHZ-HCP-075KW

- Weight: 1.00

- SKU: HZTOHZ-HCP-075KW

Available Options

100 hp horizontal centrifugal pump with 130m3/h maximum flow, 132m maximum head, and 80mm diameter of inlet and outlet.

Features:

- The centrifugal pump has a horizontal structure. The diameter of the inlet and outlet are the same. If a protective cover is added, it can be used in the open air.

- It is easy to install and maintain. There is no need to dismantle the pipeline system, just lift off the conjunction flat nut of the vertical pump. Then, all the rotor parts can be taken out.

- A horizontal centrifugal pump can operate in series and parallel connection according to the requirements of flow and head.

- The installation angle of the pump outlet can be 0°, 90°, and 180° to meet different connection occasions.

Specifications:

| Model | HZTOHZ-HCP-80-315I | ||

| Weight | 800kg | ||

| Size | 650*1210*560mm | ||

| Power | 100 hp (75kW) | ||

| Phase | 3 phase | ||

| Input voltage * | AC 220V, 230V, 240V, 380V, 400V, 415V, 440V, 460V, 480V | ||

| Input frequency * | 50Hz, 60Hz | ||

| Flow (min. flow to max. flow) | 70m3/h (308 gpm, American system) | 100m3/h (440 gpm, American system) | 130m3/h (572 gpm, American system) |

| Head (max. head to min. head) | 132m (433ft) | 125m (410ft) | 114m (374ft) |

| Efficiency | 55% | 66% | 67% |

| Inlet diameter | 80mm (3 inch) | ||

| Outlet diameter | 80mm (3 inch) | ||

| Installation angle of outlet | 0°, 90° and 180° | ||

| Nominal diameter of impeller | 315mm | ||

| Pump type | Booster pump | ||

| Number of stages | Single stage | ||

| Motor type | Y/Y2 series motor | ||

| Motor speed | 2900rpm | ||

| Impeller material | 304/316 stainless steel | ||

| Seal material | 304 stainless steel, tungsten carbide, fluorine rubber | ||

| Inlet max. pressure | 1MPa (145 psi) | ||

| (NPSH)r | 4.0m | ||

| Usage | Water or liquids compatible with pump component materials. 1. The volume of solid particles should be less than 0.1% in unit volume, and the granularity should be less than 0.2mm. 2. The temperature should be lower than 60℃. | ||

| Environment | Temperature: <40℃, humidity: <95%, altitude<1000m | ||

| Warranty | 12 months | ||

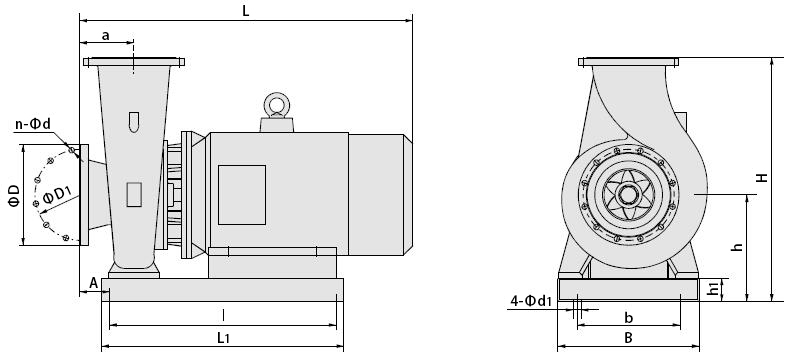

Horizontal centrifugal pump dimension (unit: mm):

| Boundary dimension | Base dimension | Flange dimension | |||||||||||

| h | H | L | a | A | L1 | B | l | b | h1 | 4-Φd1 | D | D1 | n-Φd |

| 325 | 650 | 1210 | 125 | 85 | 900 | 560 | 820 | 360 | 100 | 4-Φ22 | Φ200 | Φ160 | 8-Φ18 |

Tips: Requirements for the centrifugal water pump installation position

The premise of continuous operation of the centrifugal pump is that the suction pipe must be filled with water before the pump start-up, otherwise the water will not be sucked up. To ensure that the suction pipe has no evacuation phenomenon due to pumping termination, it is necessary to solve the problem that the water suction pipe can be filled with water in both water pump stoppage and operation conditions. There are two installation positions on site:

- The pump spindle is located below the water surface of the suction pool. This method is also called the self-irrigation method. In other words, regardless of whether the water pump is running or not, the suction pipe is always under the action of the hydrostatic pressure of the water surface and the hydrostatic pressure of the water level of the pool to the center height H of the suction pipe, the suction pipe is always in a status of full of water.

This method is quite common. The water pump can be started and stopped at any time, requiring no measures. - The water pump spindle is above the suction water level. When the water pump stops operating, the water in the suction pipe will flow back into the pool by the elevation difference. The suction pipe will be drained. If the water pump is started once again, it is required to fill in the suction pipe. However, such an operation is not practical. At this moment, it is only required to install one bottom valve on the end of the suction pipe(namely, play the role of the check valve), and the emptying condition of the suction pipe can be stopped.

In such an installation, one water pump can be connected to the water outlet pipe of the water pump for water filling. The air in the suction pipe and pump body can be eliminated through the vent valve on the pump body. Generally, if the bottom valve has no fault, the water pump can work normally.

Horizontal Centrifugal Pump User Manual